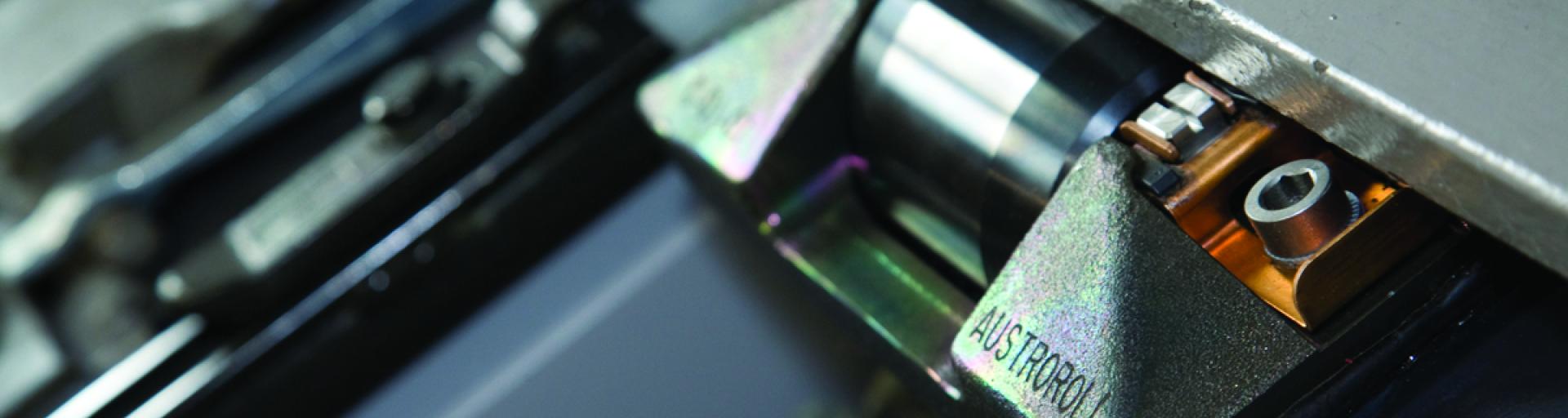

Rollvorrichtung für Eisenbahnweichen

Wartungsfrei, robust und störungsresistent - Austroroll setzt Maßstäbe bei wartungsfreien Zungenrollvorrichtungen für Eisenbahnweichen. Durch den Einsatz von Austroroll entfällt die übliche Schmierung der Gleitstuhlplatten in der Weiche vollständig. Das weltweit einzige dauerhaft elastisch gelagerte Rollensystem reduziert den Umstellwiderstand um bis zu 60%. Wartungskosten, Betriebsstörungen und letztendlich Verspätungen im Zugverkehr werden so erheblich reduziert.

Mit dem Einsatz von Austroroll können bei jeder Weiche über 20 Liter Schmiermittel jährlich eingespart werden. Das ist nicht nur umweltfreundlich, es schont auch den Oberbau und erhöht die Arbeitssicherheit beim Kunden. Das spezielle Austroroll Design garantiert beim Umstellen der Weiche, dass die Weichenzunge über die Rolle verschleißfrei und extrem reibungsarm in ihre Endlage rollt und nicht mehr gleitet. Seit 1992 wird das Rollensystem kontinuierlich gemeinsam mit unseren Partnern weiterentwickelt und weltweit verbaut.

Mit unseren Video-Anleitungen für die Montage von Austroroll unterstützen wir Sie nun auch online!

Dauerhaft elastische Lagerung

garantiert den permanenten Kontakt der Rolle mit dem Zungenfuß und optimiert das Aufrollen der Weichenzunge.

Austroroll-Komponenten

Hergestellt aus korrosionsbeständigen und hochfesten Werkstoffen.

Wirtschaftlich und robust

Eine kurze Amortisationsdauer von 2 Jahren, geringe Einbaukosten und eine lange Lebensdauer machen Austroroll zu einer wirtschaftlichen Lösung - egal ob auf Hochgeschwindigkeitsstrecken, im Regionalnetz, bei Metros oder bei Industriebahnen. Seit 2012 können auch bewegliche Herzstücke mit Austroroll®-HSR ausgerüstet werden.

Produktvideo

Austroroll® - Die wartungsfreie Rollenvorrichtung

Ansprechpartner

Get in touch – Unsere Experten für Rollvorrichtung für Eisenbahnweichen

Robert Kollouch, BU Engineered Products | Head of Railway Engineering

+43 2256 81145 120 robert.kollouch@wieland.com

Unsere Produktauswahl

Rollvorrichtung für Eisenbahnweichen – auf einen Blick.

Unser gesamtes Produktsortiment

Um das Produktportfolio eines bestimmten Standorts anzuzeigen, wählen Sie bitte das Unternehmen aus:

Sie kennen Ihren Suchbegriff bereits? Dann nutzen Sie doch einfach unsere Volltextsuche. Sie erhalten eine Liste mit allen passenden Inhalten.